Services

Tig Welding

Often used for welding 4130 Chromoly as well as stainless, aluminum, and mild steel, TIG stands for tungsten inert gas and is technically called gas tungsten arc welding (GTAW). The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. The tungsten and weld puddle are protected and cooled with an inert gas, typically argon.

MIG Welding

Primarily used on mild steel applications MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas

Tube Bending & Tubular Frame Construction

We can bend, notch, and weld many varieties of material.

Sheet Metal Fabrication

With pressbrake capabilities up to 1/4"

Powder Coating

Multiple materials, multi coating, bead blasted for proper adhesio with unlimited color options.

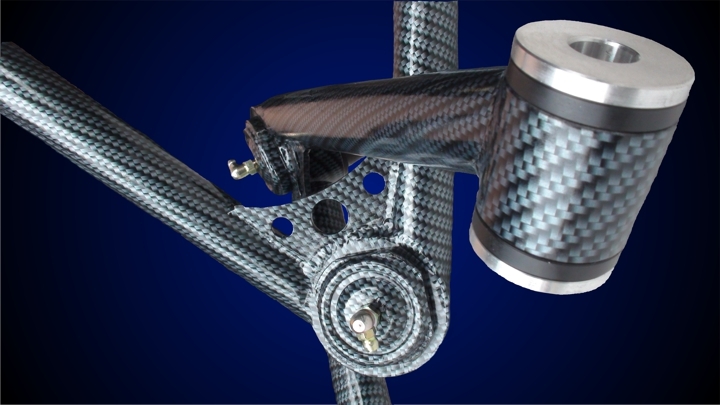

Hydrographics

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, watermarbling, cubic printing, Hydrographics, or HydroGraphics, is a method of applying printed designs to three-dimensional surfaces.

join our

email listYou’ll be first to know about Magnum Force products, discounts and special events!